Hella G4 is a new-production, custom designed CPU card for the Power Macintosh G4 "AGP Graphics" series of computers, including,

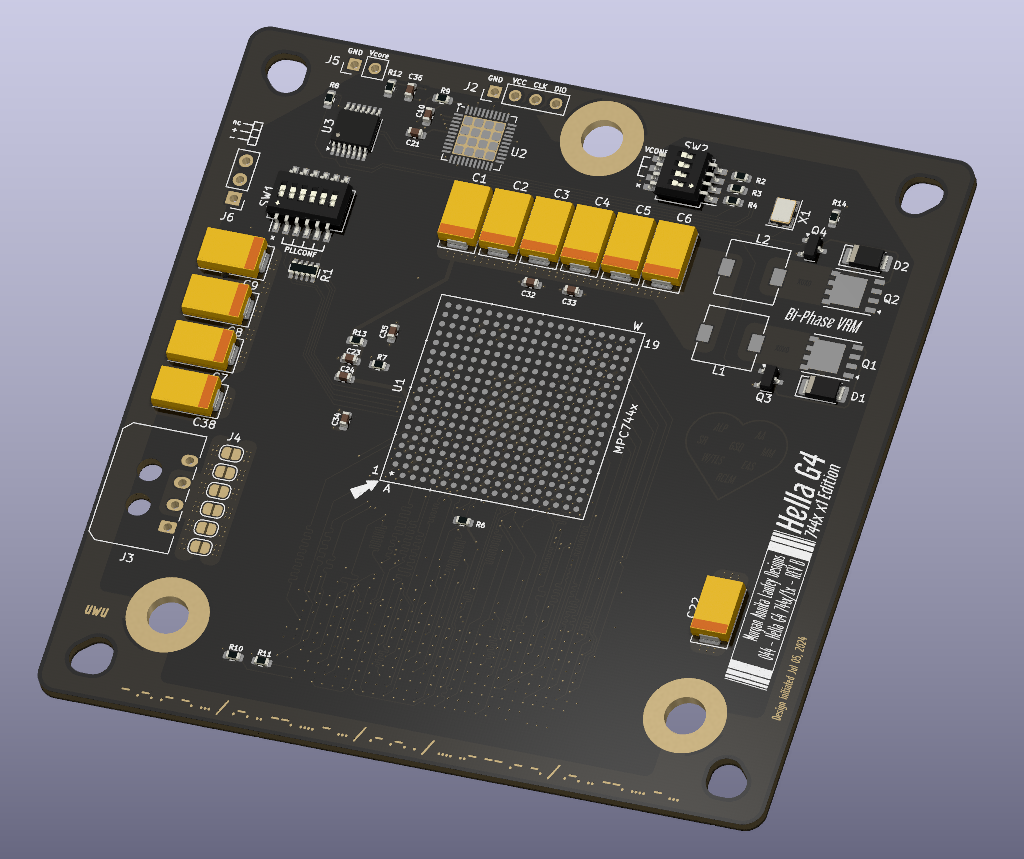

It uses an 8-layer PCB and follows the standard 90x90mm square CPU card shape found in low speed single CPU PowerMac G4 systems, except for a small 12mm extrusion for the optional external power connector, which is designed to accept a Molex Micro-Fit 1x4-pin plug and will include a number of power input adapter options to allow it to connect to either a Molex/Peripheral power connector, the G4 Quicksilver's 12v input post, or an ATX 12v compatible 4-pin power input. This small form factor will allow for it to fit in any G4 model with no modifications to the machine. Due to a desire for maximum cooler compatibility, it features triangular mounting holes to accept both Intel LGA-1366/2011 (80x80mm) and LGA1700/1851 (78x78mm) mounting hardware as well as original G4 heatsinks (78x80mm). All components on the main body of the card have a strict 3.7mm height limitation with the sole exception of the power input connector, with all components within the vicinity of the CPU die being no more than 3mm tall so as to not create obsctructions near the CPU.

The non-plated holes near the edge of the PCB follow the standard Intel mounting pattern for LGA 1366, but a custom backplate may need to be created to fit around the surface mounted diodes, mounting posts, and the 300-pin Mezzanine connector. I've also created a bracket that will clip onto the card and allow the mounting of AMD clip-style cooling solutions.

While the external power connector is designed to feed 12V power from an external source, typically a PC power supply adapted for use with the system or perhaps a Quicksilver's original power supply with an appropriate cable to invert the polarity of the 12v connector, it can also be configured for use with 5v bus power through the use of six solder bridges. This will allow it to run in unmodified G4 systems as an original CPU card would have.

The current processor card uses a two phase, software-controlled VRM capable of delivering well in excess of 40a of current at a range of both input and output voltages, with the current target range being a 5 to 12v input creating a 1.2 to 1.55 volt output for MPC 7445, 7447/A/B, and 7448 CPUs being the target devices. This VRM could likely handle two CPUs well enough, though exactly how that is intended to work, I'm not sure.

The processor's PLL configuration is set via a DIP switch mounted to the left edge of the PCB, allowing for a full range of multiplier settings from 1x to 28x, with core clocks of 1.7GHz expected to be safe, and 2GHz considered to be an ideal maximum with either good 7447B or 7448 processors installed.

Voltage settings are accomplished with a second DIP switch at the top-center of the card, which interfaces with the microcontroller software as an input, with eight possible target values in 50 millivolt increments (1.2v, 1.25v, 1.3v, 1.35v, 1.4v, 1.45v, 1.5v, 1.55v). This is maintained with a relatively simple 4MHz polling via an analog-to-digital converter on the ATMEGA32U4 microcontroller. This allows 3.5 millivolt precision when using the 1.8v I/O voltage as a reference, and it will switch alternating phases on and off as the real output voltage drifts above or below this target threshold.

The microcontroller is interfaced with via either an SWD interface for simple programming, present near the top-center mounting hole, as well as USB for general purpose communication, present via a Mini-B connector on the underside of the board.

Small-batch production of high-precision PCBs is not the biggest pain point when it comes to the production, with a PCB cost of roughly $17/unit with a minimum quantity of 5 from JLCPCB, with costs decreasing as unit numbers increase.

Adding a color to the PCB other than green is a flat $31.50 fee, making unit costs,

The bill of materials for each unit not including the PCB is roughly $100, if a 7447B is used. This includes,

Depending on the board quantities and colors, the single CPU as a kit may have a material cost to me in the ballpark of $130 after shipping and taxes and a lead time in the 2-3 week range, perhaps a retail price in the $200 range if I was to assemble it.

If I was to assemble a complete unit then I would have to acquire the proper tools to do so. A board preheater, a BGA nozzle for my hot air station, a programmer for the microcontroller, and solder paste for the many many SMD components.